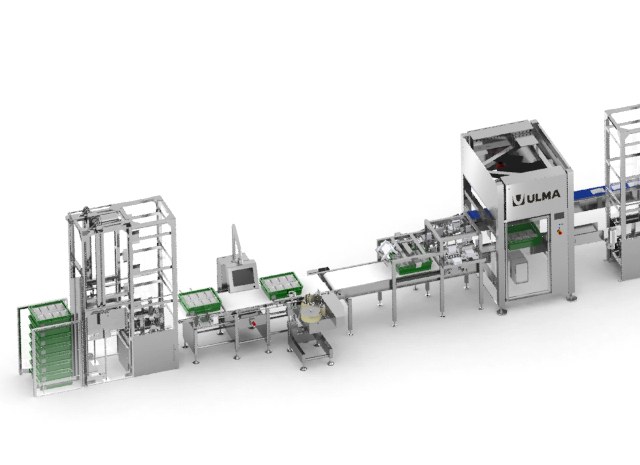

Complete solution for packaging of shredded cheese with plastic crates

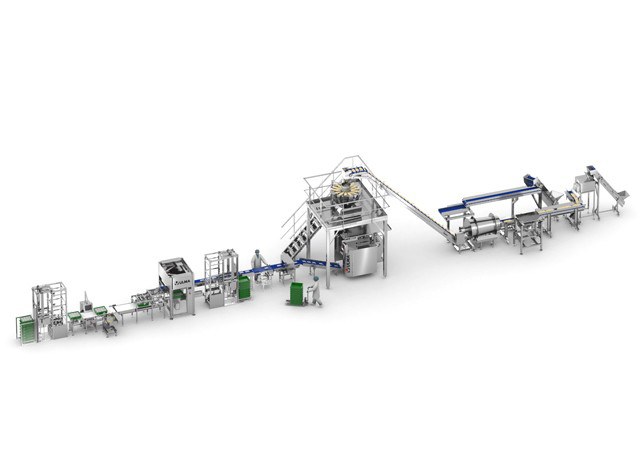

Complete solution for packing grated cheese with automatic vertical bagger

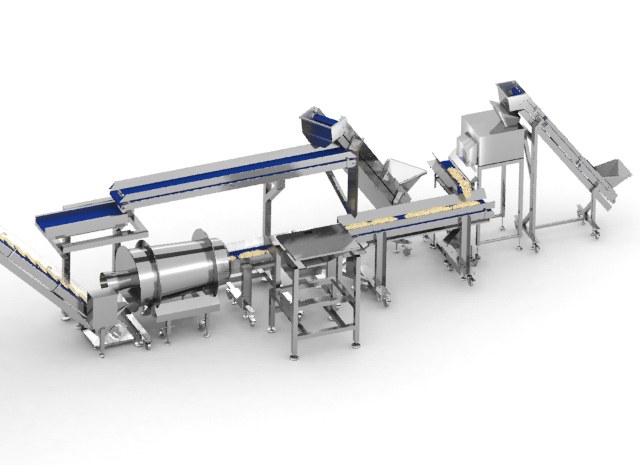

The packaging line begins with a cheese grater, the result of which is picked up by a belt that automatically reads the flow of received cheese, adding anti-caking (usually potato starch) in the correct proportion with respect to the reading of the received cheese flow.

Subsequently, all the cheese is transported to the tumbler, which homogenizes the mixture so that the product will not become compacted once packaged.

The product rises to the multi-head combination weigher that makes the necessary doses for each bag, transferring the product to the vertical packaging machine.

Both the multihead and the vertical packaging machine are flexible and designed to work with different bag formats. ULMA has different packaging models designed for the dairy sector, opting for the best model in each case, depending on the characteristics of the application in factors such as speed, dose and reclosable solutions.

The installation has an automatic destacker of empty plastic crates to feed the robotized case packing cell.

After case packing, an automatic crate stacking is carried out for which it is essential that previously the bar closure is done, which is also done automatically inline.

The case packing cell receives both the bags of grated cheese and the empty crates. Case packing is performed by a robot, forming the mosaic of bags according to the dimensions of bag and cratex.

Just after case packing and before stacking, a labeler intregated in line labels each plastic crate with the identification data corresponding to the product in production.