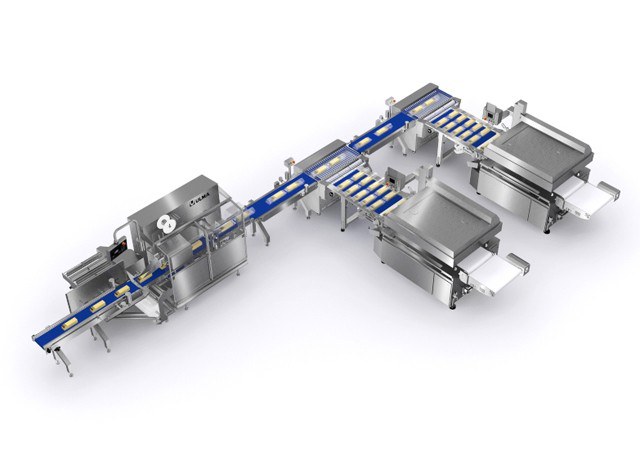

Vacuum cheese bar packaging automation with double transfer to vacuum chambers

Automatic vacuum packaging solution for cheese bars with double transfer system to vacuum chambers.

The FLOW-VAC® system offers, through a simple solution, the possibility of automating the vacuum packaging process, with a very competitive investment level. It consists of a lower reel machine, in which the film is fed under the product, which is essential to avoid contamination of the sealing area.

The vacuum bag is formed around the product creating an hermetic seal along the bag (longitudinal seal). The FLOW-VAC® system detects the start of each product and automatically feeds it onto the film in such a way that each one of the products is sealed with a high-quality hermetic transversal seal. Both sealing systems are equipped with the latest technology in order to provide seals with high reliability. The excess film generated in the longitudinal seal is removed from the package and accumulated by means of a scrap collector system, which gives the package an excellent aesthetic appearance thanks to the narrow longitudinal seal.

MAIN ADVANTAGES

- High flexibility.

- Automation of the process.

- High productivity.

- Lower film consumption.

- Less labor.

- Less contamination from seals.

- Fewer vacuum leaks.

- Lower stock of bags.

The double automatic transfer system patented by ULMA Packaging allows to obtain from the packaging machine bags that are alternately open at the front and at the back, so that it is possible to automate the loading of the packages to a double sealing bar vacuum chamber belt, using a 90º transfer system.

A 90° transfer system pairs the packages in the buffering belt of the vacuum chamber so that both seal bars can be utilized. If the products are not small enough to be paired, an auto-detect system will load the product as a single item.

The high productivity of the FLOW-VAC® system even allows the loading of up to two vacuum chambers to be automated, by using two 90º transfer systems.

This automatic system increases productivity and reduces production costs.

The automatic transfer system allows integration and synchronization with vacuum chambers from various manufacturers.

The two vacuum chambers are responsible for making hermetically sealed and vacuum packages to extend their shelf life.