ULMA Packaging returns to ProSweets 2026 with the most innovative solutions for the confectionery and sweets industry

What Can You Find at Our Booth? Hall 10.1, Stand F008

In line with our commitment to continuously adapt to the specific needs of our customers, we will be showcasing some of our latest developments designed for the confectionery and snacks industry.

Hermetic Packaging Solution for 5kg Chocolate Blocks

Versatility, protection, and efficiency in a single machine

Product safety and preservation are crucial factors for chocolate. The FM 400 Flow Pack Wrapper represents a comprehensive and adaptable technological solution. With its blend of flexibility, robustness, and compatibility with multiple materials, it is the ideal choice for manufacturers looking to raise the bar in their packaging lines.

Key benefits that make the FM 400 a high-value solution for packaging chocolate blocks:

- Extended shelf life (up to 24 months)

Hermetically sealed packaging against moisture, oxygen, and light. This protection extends the shelf life of the chocolate for up to 24 months, preserving its flavour, texture, and properties without compromising food safety. - Enhanced protection for heavy products

Thanks to its ability to work with films up to 100 microns thick and materials with aluminium layers, this solution ensures mechanical resistance of the packaging, reducing the risk of breakage or deformation. - Secure and consistent seals even under demanding conditions

The Box Motion (Long Dwell) sealing technology ensures a hermetic, high-quality seal, even with technical films or complex sealing requirements. - Versatility to adapt to different presentation formats

The FM 400 allows quick and easy transitions between various bar sizes or formats, with minimal downtime. - Easy automation

The machine has been designed for seamless integration into automated packaging lines.

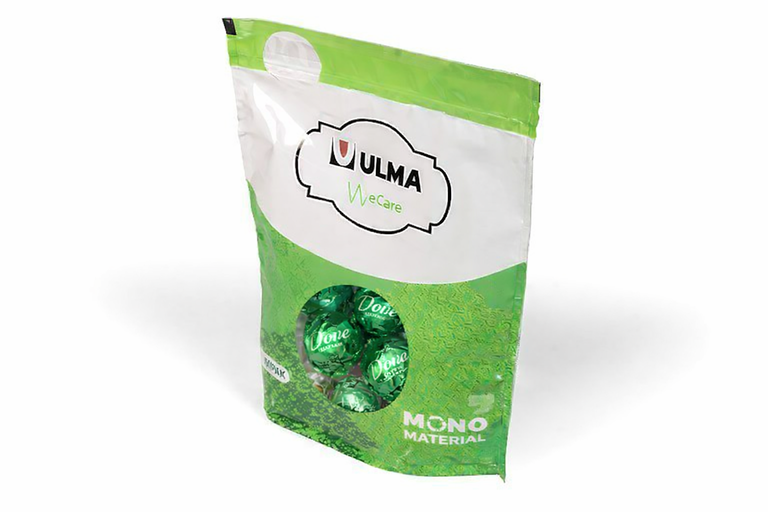

Vertical Doypack-Style Packaging Solution

Performance, cost savings, and premium presentation in one machine

In the competitive world of confectionery and snacks, where efficiency and product presentation are key, ULMA Packaging introduces a solution that combines the best of both worlds: doypack and pillow-pack formats with high added value, produced directly in-line and at an optimised cost.

- Enhanced shelf appeal with superior-finish packaging

The system enables doypack-style packaging with a premium finish, comparable to pre-formed solutions, enhancing the product's perceived quality at the point of sale. - Maximum efficiency: up to 80 packs per minute

This solution is designed for high production speeds, capable of reaching up to 80 packs per minute, ensuring smooth operation even on high-demand lines. - Significant savings on packaging costs

By forming the packages directly on the line, manufacturers can save up to 50% compared to using pre-formed doypack pouches, cutting costs without compromising packaging quality. - Reduced film consumption: more sustainable and cost-effective

The innovative cutting system eliminates film waste, saving 4mm of film per pack. This not only reduces material consumption but also enhances the sustainability of the process.

Digitisation, ease of use, and full process control

During ProSweets 2026, visitors will have the chance to explore our advanced user interface, featuring a 10” colour touchscreen managed by an industrial PC, this intuitive interface allows for seamless integration with MES, ERP, and SCADA systems, as well as tools for OEE analysis and, optionally, monitoring of energy and material consumption, key factors in boosting profitability and moving towards a more sustainable production model.

Visit us at Hall 10.1, Stand F008

If you’re looking for solutions to help you automate processes from packaging to palletising, improve line efficiency, reduce costs, switch to sustainable materials, and offer a more attractive product on the shelf, we invite you to visit us at ProSweets 2026.

If you’d like to learn more or schedule a meeting with our team, don’t hesitate to get in touch with us. Come and see for yourself how our solutions can help you optimise production, differentiate your brand, and respond to evolving market demands.

We look forward to welcoming you at Hall 10.1, Stand F008.