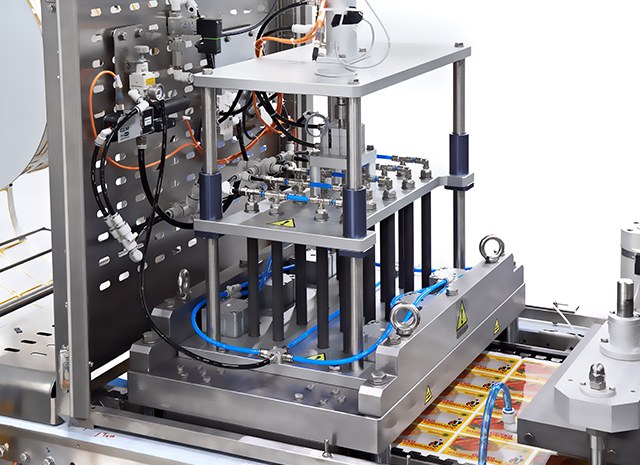

TFS 600 hygienic design thermoformer

Full sanitisation specification thermoforming machine for flexible or rigid film with modified atmosphere (MAP) and vacuum options. The highest performance level thermoformer.

The TFS 600 model is the top of the range, new ULMA TFS thermoforming line. This is an entirely new machine design concept. ULMA has redesigned every section of our thermoforming machine to surpass the rigorous hygiene and deep cleaning requirements demanded by today' s food packaging industry.

We have worked in partnership with the some of the most advanced design, research and innovative centers around the world. This, coupled with our 50 years experience here at ULMA, has allowed us to offer a new line of thermo-forming machines providing superior levels of efficiency, reliability and hygiene.

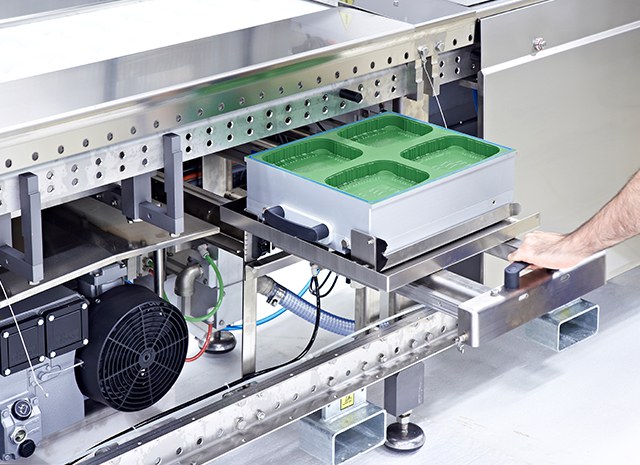

Within our new line of products, the 600-700 series allows complete adaptability in terms of pack format and production. This is largely due to its modular construction, which provides the ultimate in versatile packaging solutions.

- Easy format change.

- UPC control system:

- 10" colour touch screen display.

- Easy and user friendly.

- Multi-language and characters support (cyrillic, arabic, katakana ...).

- Control and display programs easily updatable (USB or Ethernet).

- Security backups to pendrive (USB).

- Access protection with 3 permission levels.

- Ethernet interface.

- Remote view and control system same as the one available in the HMI at the machine.

- Display of current rate. Cycle optimization tools based on time monitoring of each station.

Construction features

- Modular construction.

- Stainless steel frame.

- Safety standard according to "EC" regulations.

- Modular machine that can be enlarged depending on the project.

- Easy access to internal components of the machine, with removable lateral covers.

- Optional additional dies available for the machines.

Ease of maintenance

- Minimum maintenance.

- Maintenance program integrated in the control panel.

- Remote Support Management (RSM). Connection is made by Ethernet with http access (internet).

- Original top level commercial components.

Solutions

High performance multi-purpose machines. With a long list of specific devices developed to meet the needs of each product to be packaged, production requirements and pack specifications, these machine models can respond to all types of packaging needs.

Most common options

- Dosing and product loading systems.

- Die/reel holder trolley.

- Pack convergers.

- Coding and printing systems.

- UST seal test checker (ULMA seal tester).

- Metal detectors.

- Integration in end of lines.