Aurora Coop Boosts Production with a Turnkey Automation Solution from ULMA Packaging

This collaboration, implemented across several of Aurora Coop’s plants, integrates complete packaging and automation solutions that enhance operational efficiency, reinforce food safety and ensure full process traceability.

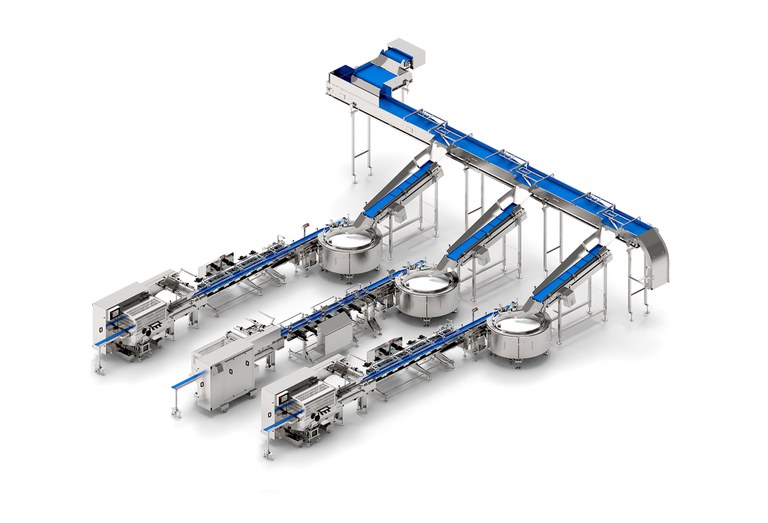

Full Automation: From freezer exit to end-of-line

ULMA Packaging has engineered a customised system that connects every stage of the production process, from the freezer exit to the end of the line. This turnkey solution stands out for its scalability, flexibility and adaptability, supporting Aurora Coop’s growth and technological evolution.

Key solutions implemented

In the projects deployed at Aurora Coop’s plants, the following elements were featured:

-

Product distribution and alignment systems at the freezer exit, with automatic control of temperature and product quality.

-

Automated feeding into packaging, both horizontal and vertical, with smart synchronisation according to each line’s demand.

-

Integrated automatic packaging systems incorporating technologies such as Flow Pack (HFFS), Thermoforming (MAP/Vacuum), Traysealing (traysealers), Vertical (VFFS) and Stretch or Shrink film, selected according to the specific characteristics of each product.

-

Product alignment and grouping modules that optimise workflow and reduce bottlenecks.

-

Robotic case-packing and palletising solutions, customised to each plant layout, guaranteeing logistic standardisation, safety and traceability control.

Impact on Aurora Coop’s production

Thanks to the integration of ULMA Packaging’s solutions, Aurora Coop has achieved a new level of operational efficiency and stability, especially in low-temperature environments. The comprehensive automation has reduced dependency on manual labour and increased production capacity in a sustainable manner.

+ Efficiency: continuous, standardised processes that eliminate interruptions and improve production flow.

+ Safety: reduced manual intervention and enhanced food‐safety protection at every stage.

+ Product quality: more consistent packaging and precise application of MAP to extend shelf life.

+ Operational agility: faster format changes, cleaning and maintenance.

+ Logistics optimisation: from case-packing to final palletising, ensuring traceability and uniformity.

Ongoing commitment to excellence

Beyond supplying packaging equipment, ULMA Packaging delivers integrated solutions, technical consultancy and local support, contributing directly to the evolution of Aurora Coop’s manufacturing infrastructure.

This alliance continues to advance with new project phases underway and the confidence that technology and trust go hand in hand when the goal is to deliver the best to the market.

Every production line is unique. At ULMA Packaging, we turn your challenges into growth opportunities, with automated, efficient and safe solutions, tailored to your needs.