ULMA Packaging will be displaying smart, automatic equipment and lines with sustainable packaging technologies at Fruit Logistica 2024

The leading international trade fair for the fruit and vegetable industry, Fruit Logistica, is being held in Berlin from 7th to 9th February and will bring together fruit and vegetable producers, who will get the chance to talk to our experts for advice on their packaging needs and on how to improve productivity.

The safety and protection of our customers' products and the production efficiency of their lines are our main objectives, where all our efforts are focused.

#ULMAweCare: Sustainable packaging

As such, we will be presenting sustainable packaging solutions that are designed to be recyclable within a circular economy, keeping the environmental impact of waste to a minimum and helping to reduce the taxes levied on plastics.

Our machines provide the flexibility required by a market as dynamic as the fruit and vegetable sector, being able to work with both plastic materials and others such as paper fibre-based materials, mono-materials and compostable materials.

Complete automatic packaging lines

Our extensive experience in packaging solutions allows us to offer customised and automated solutions to our customers in order to meet their packaging line needs.

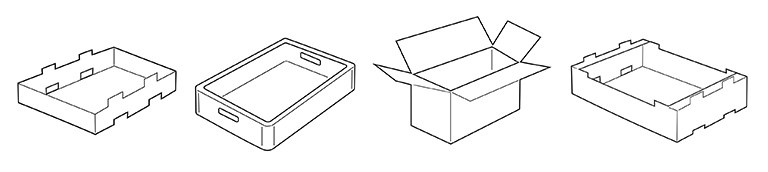

With robustness and ease of operation being key design features, this year we will be exhibiting a packaging line for fruit trays based on the TSA 680 P traysealer, which is equipped with the CP 200 automatic packing cell, which is capable of packing trays into various types of plastic and cardboard boxes.

With an output of up to 120 trays per minute, this is a quick-change traysealer that has been specially designed for fruit and vegetable products and can work with fully recyclable trays made of both RPET plastic and cardboard.

Digital solutions

Through Smart Machines and Smart Services, we provide networked packaging lines in a smart factory environment. They are equipped to collect real-time data and their monitoring and analysis tools make it possible to optimise the efficiency and return on investment of packaging lines.

Nowadays, identifying and analysing the causes of non-productivity is essential to improve the efficiency of the lines.

Machine-level features (HMI)

- OEE Data entry: this is an application that is available on our control panel (HMI) to collect production information.

- OEE Monitor: the data is analysed and the Overall Equipment Efficiency (OEE) is automatically calculated, with a real-time report being displayed in numerical and graphical form.

- LOG Event Recorder: for logging and displaying messages and alarms in files.

- Consumption analysis: Electricity, compressed air, gas, film.

- Preventive maintenance wizard: displays messages and warnings about the desired maintenance tasks.

In addition to the various modules listed above, which can be accessed via the machine's HMI, our devices can optionally be connected to the myULMA customer portal, providing a more comprehensive analysis and more advanced features.

Flexibility is a key feature: horizontal and vertical packaging for fruit and vegetables

It is worth highlighting the various packaging options that we will be showcasing at the stand with our flowpack machines and vertical wrappers.

Packaging solutions for products with and without trays which are made from alternative materials designed for products such as a variety of fruit and vegetables.

Flexibility is a key, defining feature of these machines, as they can be easily adapted to new formats, products and materials. They are designed to work at a high productivity rate with the reliability for which all our machines are renowned.

Equipment and applications at the stand

The list of equipment as well as applications that will be showcased are detailed below.

- SIENNA Hi-Tech flow pack wrapper for trayless vegetables. The packaging is made with paper film that has a breathable mesh window made with paper and bamboo fibers.

- ATLANTA flow pack wrapping machine for packaging fruits and vegetables in cardboard trays. The packaging is made with a plastic-free compostable film composed of cellulose fiber.

- VTC 840 vertical bagger for packaging fruits and vegetables in steady bottom packages.

- Packaging line for fruit trays with TSA 680 P traysealer and CP 200 automatic case packing cell. The cardboard trays are sealed with a compostable film composed of cellulose.

More information

If you require more information, consult the following success stories and sustainable solutions detailed below.

Case studies

- Moyca Grapes chooses ULMA Packaging to increase its packaging capacity. Link

- Orogel optimizes its production capacity for sustainable packaging of frozen vegetables through ULMA's BETTER-SEAL™ system. Link

- Green Factory Group - Packaging optimisation with the VENTURI™ system. Link

- ULMA Packaging scales up pioneering produce Natoora's plastic-free packaging operations in United Kingdom. Link

- Fincas Bethengara chooses ULMA Packaging for the automation of herb and sprout packaging with the Venturi™ system. Link

Sustainable packaging solutions

- Paper based packaging solutions for fruit and vegetables. Link

- Sustainable packaging for fruits and vegetables. Link

- Plastic free packaging solution for fruits and vegetables in Flow Pack. Link

- Vertical wrapping machines (VFFS) designed to work with sustainable materials. Link

- Sustainable packaging solutions in Traysealing machines. Link